3-D Printed Electromagnetic Components and Systems

|

Additive manufacturing technologies, often called 3D printing, have received much attention recently with impressive demonstrations ranging from musical instruments, to vehicles, to housing components or even entire buildings. Several research projects have been carried out at our group in the area of 3D printed electronics such as waveguides, antennas, lenses and holographic devices for GHz to THz operation. |

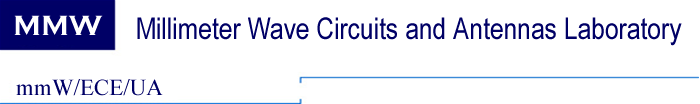

| 3-D Printed Bandgap structures |

We have fabricated several structures with 3D electromagnetic bandgaps in the 100-400 GHz range. Characterization of these structures via THz Time-domain Spectroscopy (THz-TDS) shows very good agreement with simulation, confirming the build accuracy of the approach. This rapid and inexpensive 3-D fabrication method may be very useful for a variety of potential THz applications. |

The Fabricated Polymer THz WPS |

| |

| The Fabricated Polymer Johnson EBG Structure |

|

| Z. Wu, J. Kinast, M. Gehm, and H. Xin, "Rapid and Inexpensive Fabrication of Terahertz Electromagnetic Band Gap Structures," Optics Express, vol. 16, no. 21, pp. 16442-16451, Oct. 2008 |

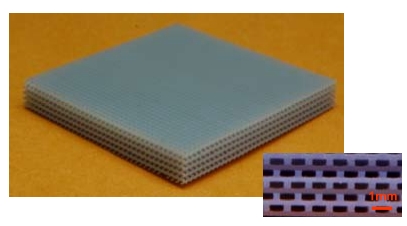

| 3-D Printed THz EMXT Horn Antenna |

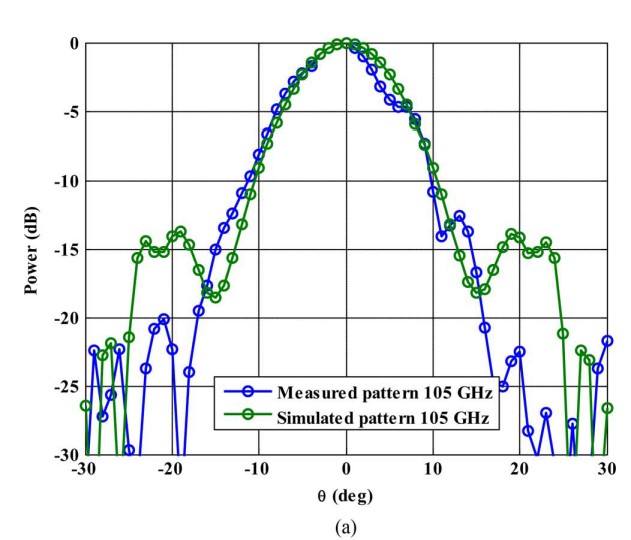

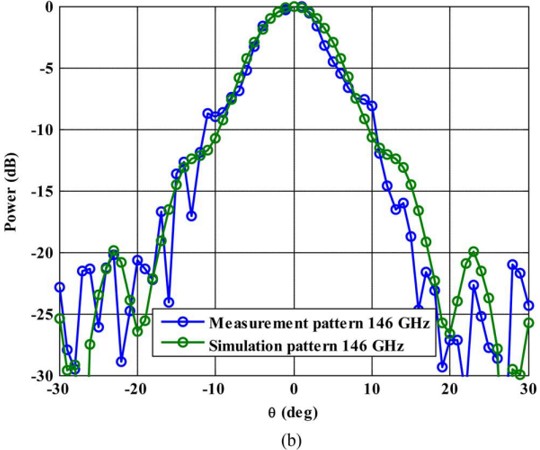

An all-dielectric terahertz (THz) horn antenna based on hollow-core electromagnetic crystal structure is designed, fabricated and characterized. Simulation shows that the antenna works above 100 GHz, with better than 30 dB return loss and highly directional radiation pattern. Fabrication of the antenna is done using a THz polymer-jetting rapid prototyping technique. |

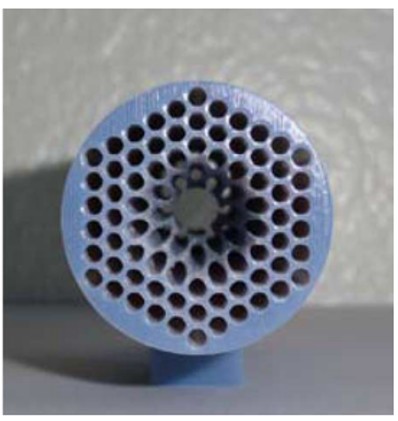

| Photos of the Fabricated THz EMXT Horn Antenna |

|

|

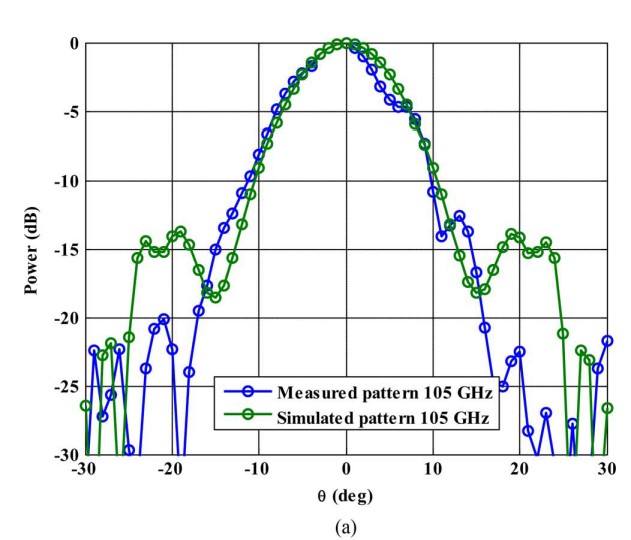

| Antenna Pattern at phi=0 Plane at 105 GHz and 146 GHz |

|

|

| Z. Wu, M. Liang, W. Ng, M. Gehm, and H. Xin, "Terahertz Horn Antenna Based on Hollow-core Electromagnetic Crystal (EMXT) Structure," IEEE Trans. Antennas Propag., Vol.60, No.12, pp.5557-5563, Dec. 2012. |

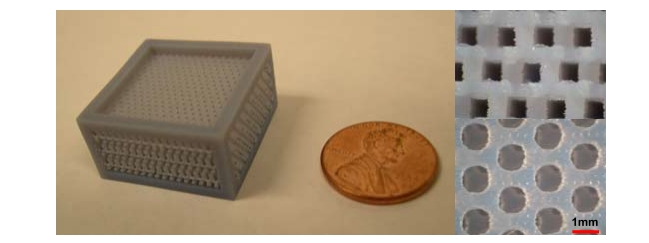

| 3-D Printed THz Waveguide |

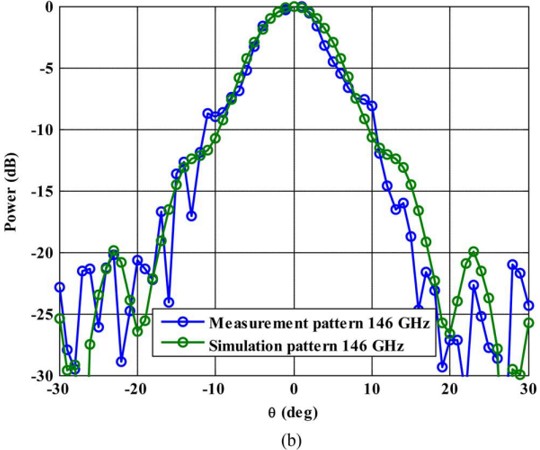

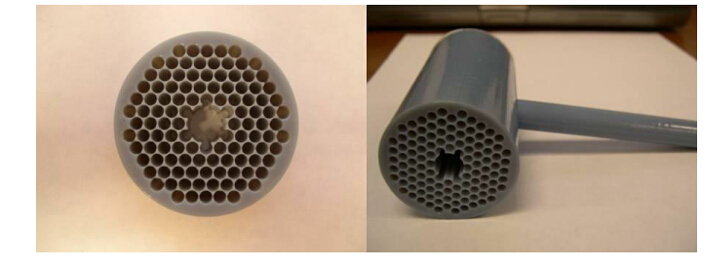

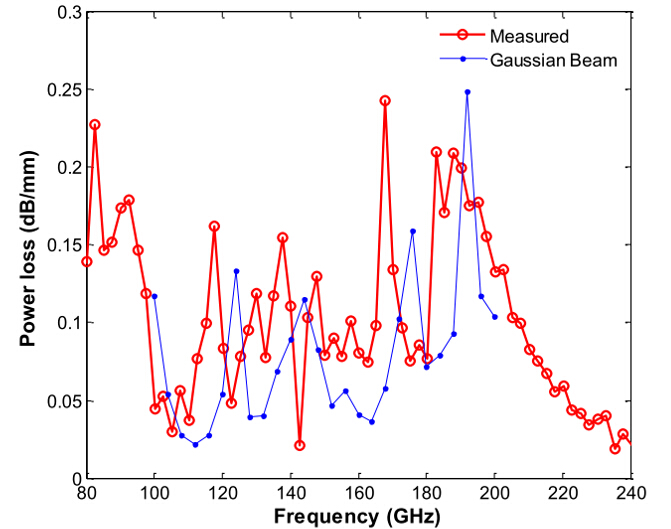

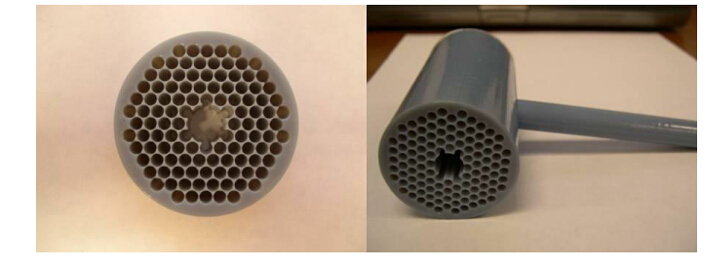

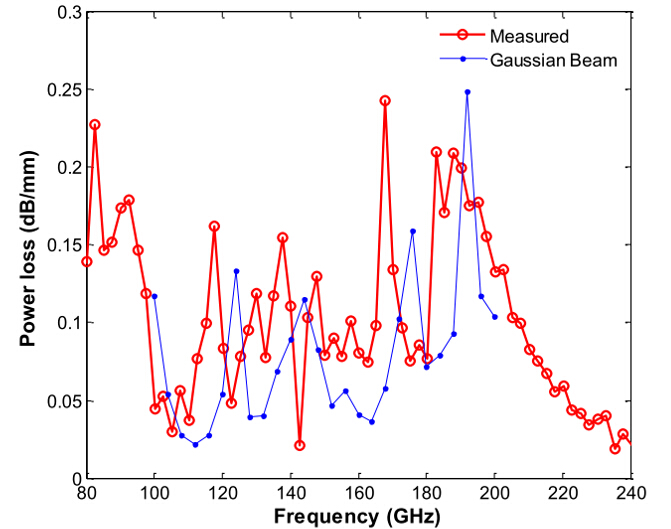

An all-dielectric THz waveguide has been designed, fabricated and characterized. The design is based on a hollow-core electromagnetic crystal waveguide, and the fabrication is implemented via polymer-jetting rapid prototyping. Measurements of the waveguide power loss factor show good agreement with simulation. As an initial example, a waveguide with propagation loss of 0.03 dB/mm at 105 GHz is demonstrated. |

| A Fabricated THz Waveguide |

|

| Power Loss Factors under Gaussian Beam Excitation |

|

| Z. Wu, W. Ng, M. Gehm, and H. Xin, "Terahertz Electromagnetic Crystal Waveguide Fabricated by Polymer Jetting Rapid Prototyping," Optics Express, vol. 19, no. 5, pp. 3962-3972, Jan., 2011. |

| 3D Rapid Prototyping of Terahertz Computer-Generated Volume Holograms |

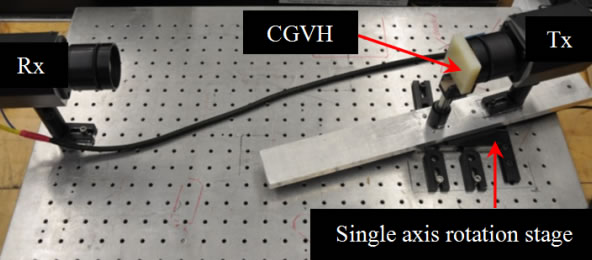

| New 3D rapid prototyping technology has allowed for fast and inexpensive fabrication of terahertz gradient-index components. We have shown that this new commercially available 3D RP technology can be successfully used to fabricate functional THz CGVHs quickly and inexpensively. |

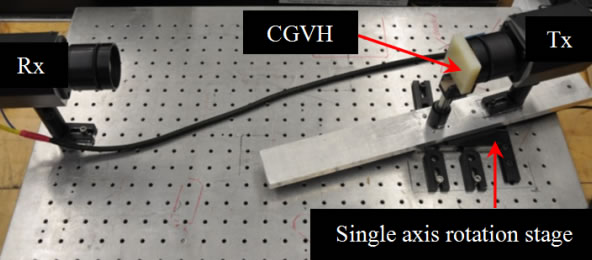

Experimental measurement setup of the THz CGVH. |

|

| Ng, W.; Golish, D.R.; Xin, H.; Gehm, M.E., "3D rapid prototyping of terahertz computer-generated volume holograms," 2012 37th International Conference on Infrared, Millimeter, and Terahertz Waves (IRMMW-THz), Sept. 2012 |

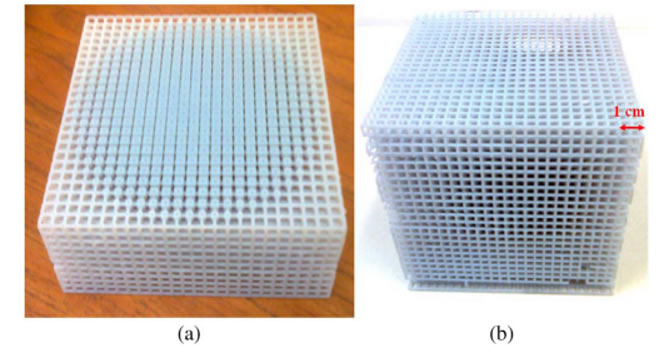

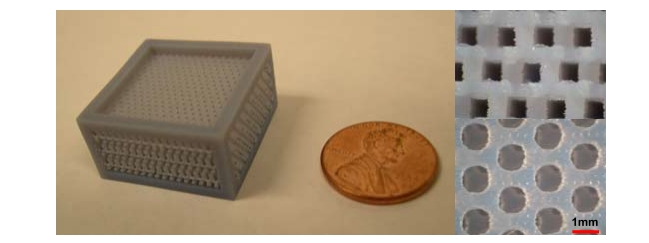

| 3-D Printed Luneburg Lens |

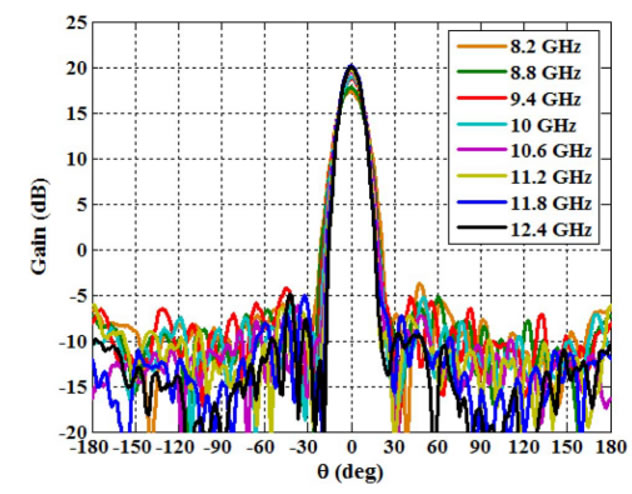

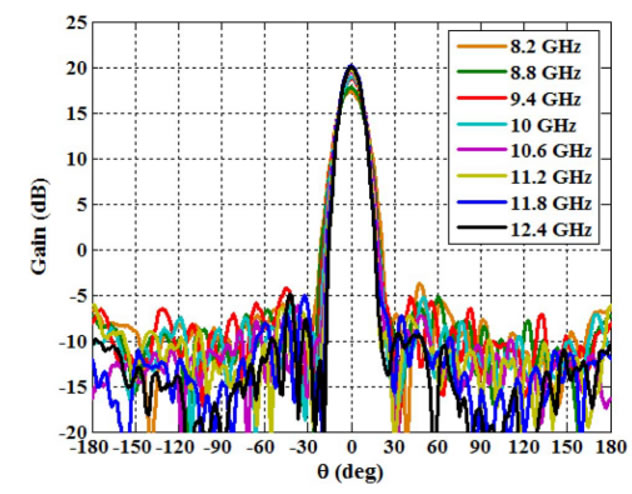

In this work, we designed, built, and tested a low-gain 20 dBi Luneburg Lens antenna using a rapid prototyping machine as a proof of concept demonstrator. A 12-cm ( at 10 GHz) diameter lens is designed to work at X-band. The measured gain of the antenna at X-band is from 17.3 to 20.3 dB. The measured half-power beam width is from 19 to 12.7 while the side lobes are about 25 dB below the main peak. |

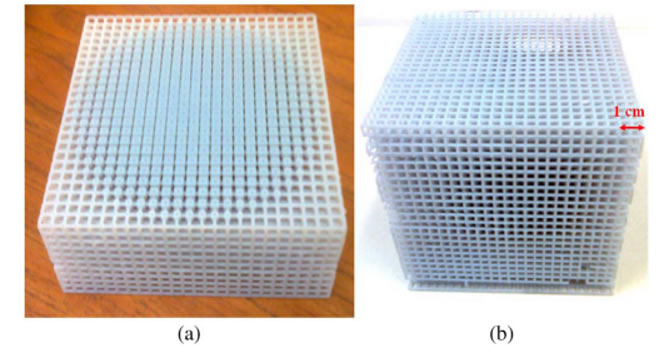

| Photograph of the Fabricated Luneburg Lens |

Measured H-Plane Radiation Gain Pattern |

|  |

| M. Liang, W. Ng, K. Chang, K. Gbele, M. Gehm, and H. Xin, "A 3-D Luneburg Lens Antenna Fabricated by Polymer Jetting Rapid Prototyping," IEEE Trans. Antennas Propag., Vol. 62, No. 4, pp. 1799-1807, Apr. 2014. |

| 3-D Printed Dielectric Reflectarry Antennas |

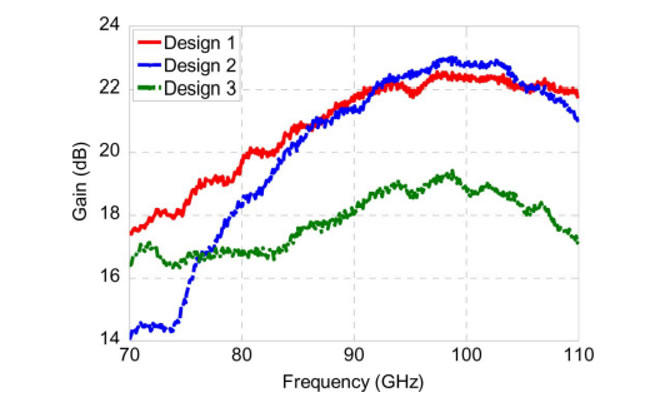

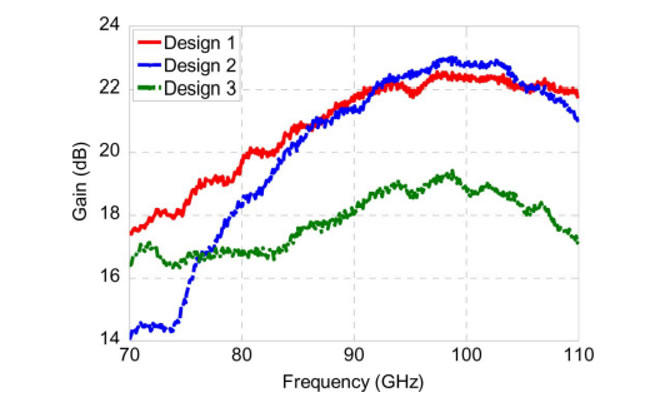

Dielectric reflectarray antennas are proposed as a promising low-loss and low-cost solution for high gain terahertz (THz) antennas. Variable height dielectric elements are used in the reflectarray designs, which allow for the use of low dielectric-constant materials. Polymer-jetting 3-D printing technology is utilized to fabricate the antenna, which makes it possible to achieve rapid prototyping at a low-cost. Numerical and experimental results are presented for 3 different prototypes operating at 100 GHz. |

| Top view of the dielectric reflectarray prototypes, Design (a), (b) and (c). |

|

| Measured Gain VS. Frequency for the Three Dielectric Reflectory Prototypes |

|

| P. Nayeri, M. Liang, R. Sabory-Garcia, M. Tuo, F. Yang, M. Gehm, H. Xin, and A. Elsherbeni, "3D Printed Dielectric Reflectarrays: Low-Cost High-Gain Antennas at Sub-Millimeter Waves," IEEE Trans. Antennas Propag., Vol. 62, No. 4, pp. 2000-2008, Apr. 2014. |

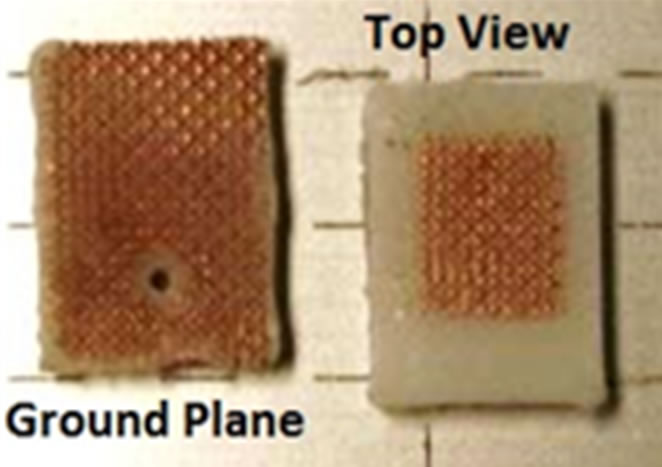

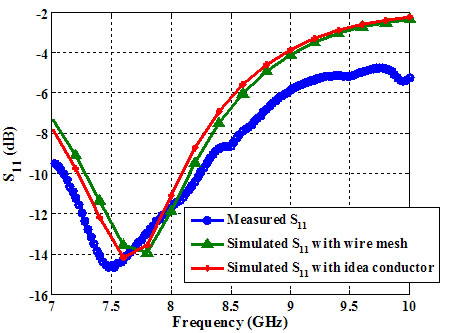

| 3D Printed Microwave Patch Antenna |

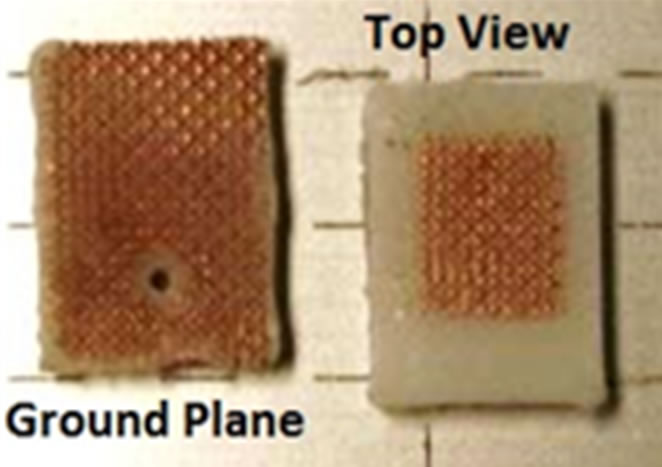

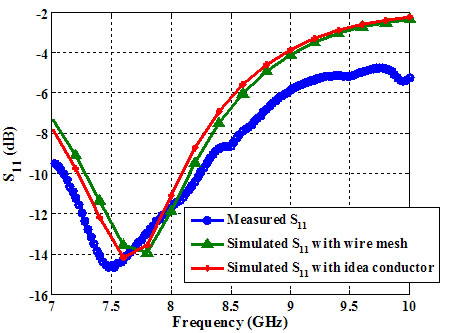

In this work, the design, fabrication and characterization of a 3D printed microwave patch antenna is presented. The antenna is fabricated by combining fused filament fabrication method for the dielectric part and ultrasonic metal wire mesh embedding approach for the conductor part.A microstrip patch antenna working around 7.5 GHz is printed and characterized to demonstrate the efficiency and accuracy of this technique. |

| Top plane and ground plane after ultrasonic embedding |

|

| Comparison of measured and simulated return losses of the printed wire-mesh antenna |

|

M. Liang, C. Shemelya, E. MacDonald, R. Wicker, and H. Xin, "3D printed microwave patch antenna via fused deposition method and ultrasonic wire mesh embedding technique ", The 2014 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, July, 2014 |